The Troll phase 3 project consists of eight wells in two templates, a new pipeline and umbilical connecting the templates to Troll A as well as a new gas processing module on the platform.

On Friday 27 August 2021 at 21.25, production started from the highly profitable Troll phase 3 project in the North Sea. The project has a break-even price below 10 dollars and CO2 emissions of less than 0.1 kg per barrel oil equivalent. The new wells are tied in to the Troll A platform and Troll phase 3 will extend the platform’s life past 2050.

Recoverable volumes from Troll phase 3, which will produce the Troll West gas cap, are estimated at as much as 347 billion cubic metres of gas. Converted into oil equivalent this amounts to 2.2 billion barrels. Investments are approximately NOK 8 billion. Arne Sigve Nylund, Executive Vice President of Projects, Drilling and Procurement declared : “Troll phase 3 is one of the most profitable projects throughout Equinor’s entire history, while at the same time featuring production with record-low CO2 emissions. This is thanks to large gas reserves and a development solution mostly based on existing infrastructure, such as pipelines, the processing plant at Kollsnes and, not least, the Troll A platform which receives power from shore. The project has been executed without serious injuries, which is extremely important.”

The Troll partners are Equinor, Petoro, Shell, TotalEnergies and ConocoPhillips.

Troll has generated substantial revenues for 25 years and will continue to do so for many years to come. Annual state revenues from the Troll phase 3 project alone are estimated at an average of more than NOK 17 billion (2021).

Around 70 percent of the deliveries to the Troll phase 3 project come from Norwegian suppliers.

The annual export volume from Troll is equivalent to approximately 8% of the EU’s gas consumption, and the further development of the Troll field also reinforces Norway’s ability to secure gas deliveries to Europe in the coming decades.

Over the course of 25 years, Troll A has contributed to transforming the energy consumption in Europe from coal to gas, with far lower greenhouse gas emissions. It was also the first platform on the Norwegian continental shelf to be electrified, as early as in 1996.

“Troll phase 3 will extend the life of Troll A and the Kollsnes processing plant beyond 2050, and the plateau period by 5-7 years. This will help secure jobs offshore, at Sandsli and at Kollsnes for both Equinor and its suppliers for several decades into the future,“ says Kjetil Hove, Equinor’s executive vice president for Exploration and Production Norway.

Like several other projects, Troll phase 3 has also felt the effects of Covid-19. The original start-up date for the project was in the second quarter of 2021, but pandemic-related labour shortages and infection control measures have delayed start-up somewhat.

“I want to thank our own employees, our partners and suppliers who have done a fantastic job during difficult times. We’ve made this happen together,” Nylund concludes.

GAS FROM TROLL HAS BEEN IMPORTANT FOR EUROPE FOR A QUARTER OF A CENTURY. WHAT ABOUT THE NEXT 25 YEARS?

Since 1996 the Troll field has been an essential exporter of gas to Europe. But why are Equinor and Norway still betting on gas when we know that the world needs more renewable and less fossil energy?

Jalal Fahadi, platform manager on Troll A has the answer : “Well, it’s because gas is a source of energy that a lot of people in the world need every day. And they’ll continue to need it for a long time to come. Gas is user-friendly, moderately priced and releases 50 per cent less CO2 than coal.”

Gas is the form of energy that can phase out coal power fastest and easiest, such as in the UK, for example, which now has the lowest CO2 emissions it has seen in more than 100 years.

In simple terms, gas is used to generate power, in heavy industry like steel and cement, and as a raw material to make mobile phones and medicines, among other things.

GOOD REASONS TO BE OPTIMISTIC

Troll is the largest gas discovery made on the Norwegian continental shelf (NCS) by far, and currently supplies as much as seven per cent of Europe’s total need for gas. This is the equivalent of the power consumption of more than 50 million European households. In comparison, there are less than 2.5 million households in Norway.

Incredibly enough, after nearly 25 years of production, more than half of the Troll gas is still in place, and this is one of several good reasons for us to be optimistic about the next 25 years as well.

Because the energy equation can’t be solved without gas:

The global population keeps growing, and we are all using more and more energy. At the same time, we’re moving toward a low-carbon society. This means that the world needs Norwegian gas if we’re going to have enough energy in the years to come. This is because renewable energy sources like solar and wind are dependent on the right weather to generate power.

WHAT WOULD BE THE FEAT OF THE CENTURY THESE DAYS?

Many would say succeeding in the energy transition.

As the first installation on the NCS, Troll A was electrified with power from shore from the very start. This has resulted in very low emissions from production. In addition to being the world’s largest offshore gas platform, it was also the heaviest mobile man-made structure when it was built in the mid-1990s. Troll A was actually named the “century’s greatest feat of Norwegian engineering” in 1999.

The energy transition is a gradual pivot to energy sources, products and services that together have fewer negative consequences for the climate and the environment.

According to the European Commission, the energy transition can be achieved by turning the current climate and environmental challenges into opportunities for sustainable economic growth and development. This is the basis for the European Green Deal, which is Europe’s joint strategy to be the first net-zero continent by 2050.

Once Europe bands together to achieve net-zero by 2050, what role will Norwegian gas play moving forward ? Because, eventually, all fossil fuels have to be removed from the energy mix.

Gunnar Egge is the production manager at Troll A : “This also includes gas, at least the way we use it today. But gas can be reformed into hydrogen, which could be very important for the energy transition.”

THIS IS WHY HYDROGEN IS IMPORTANT

Heavy industry, like steel, cement and concrete, and industries such as transport and maritime, do not currently have adequate battery technology or sufficient opportunity to generate electricity through renewable energy systems. This is one of many reasons why hydrogen is important for the world to reach its climate goals; in fact, hydrogen can be stored and used when there is a need for energy.

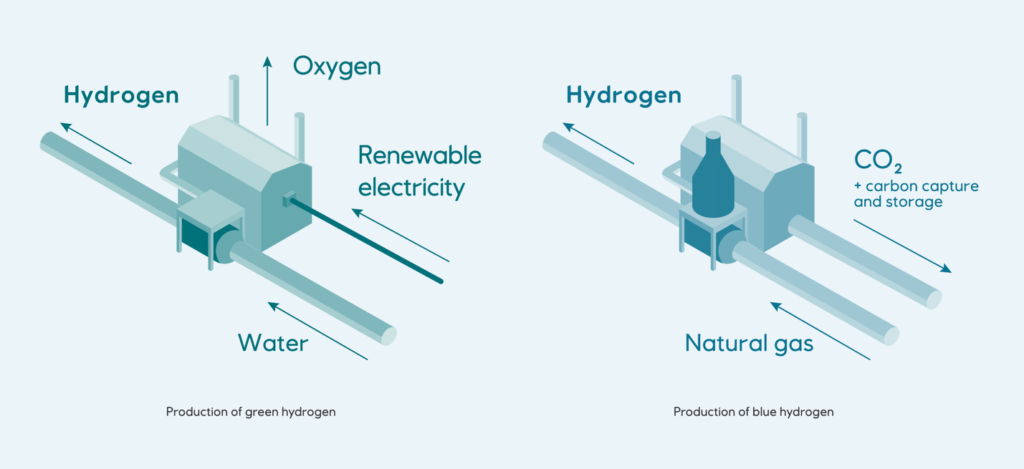

In simple terms, there are two forms of hydrogen; blue and green, and we need both to reach our climate goals. This is because both blue and green hydrogen are emission-free at combustion, despite being created in different ways:

Blue hydrogen is made by reforming gas in a process where CO2 is captured and then stored under the seabed through carbon capture and storage (CCS). This reduces the carbon footprint by as much as 95 per cent. Green hydrogen is made by using renewable energy, and is therefore entirely emission-free, even in production.

“There’s a huge volume of gas left in the Troll field and other fields. But if we’re going to be a long-term and reliable future supplier of blue hydrogen, we have to continue to explore for even more gas on the NCS” says Gunnar Egge, production manager, Troll A.

Gunnar Egge believes the energy transition is already well under way in the North Sea. He can clearly see this in his work in the Troll area, which is now also exploring opportunities to electrify the Troll B and Troll C platforms.

According to Gunnar Egge :”The energy transition isn’t a switch you can just flip, it’s several important steps. We have to continue the effort to reduce emissions in production, while simultaneously contributing to reduce emissions in consumption, for example by reforming gas into hydrogen.”