No, Xi Jinping has not developed a passion for the music of Mick Jagger (as far as I know), but China seems keen to corner the market in rare earth minerals. And they, of course, are stones. Valuable, unusual, and extremely weird but useful stones

How much do you know about gallium? I can inform you that it’s silvery-white in colour and it is so soft that it can be cut by hand with a knife. Along with mercury, caesium, and rubidium, it is one of the very few metals that could actually melt in your hand, or at a little above room temperature. It has the atomic number 31 and is described as a “post-transitional metal”. There are several. Most of the so-called “rare earth elements” (REEs) were discovered accidentally and their usefulness only became apparent with the advent of advanced technology. Strange as it may seem, there are a number of chemical elements that may belong among the post-transitional metals, but scientists aren’t sure of their position in the list of chemical elements. They include nihonium, flerovium, moscovium and livermorium, and there are various others whose status is uncertain, including polonium. Chemistry was never my strong point at school, although I blame my chemistry teacher, who seemed more interested in his own climb up the slippery (if relatively unimportant) slopes to local authority fame and glory than to imparting his knowledge to us children. Anyway, I always preferred physics. Post-transition metals have a wide variety of uses, however, and are more interesting than they may appear at first glance: aluminium and tin, for instance, are used to make cooking utensils and in electronics and soldering; bismuth helps relieve the agonies of indigestion, indium is useful in making flat-screen displays and gallium serves in the manufacture of semiconductors and fuel cells, while lead is used in making batteries, of course.

Incidentally, aluminium is known to be the commonest post-transition metal and the third most abundant element on Earth, while bismuth, which has helped so many of us, has recently been shown to be mildly radioactive. Not only will that meal you found indigestible be brought back through vomiting; perhaps it may even glow in the dark.

Although they’re referred to as “rare-earth elements”, they’re not really very rare at all. It’s more accurate to say that there is quite a lot of most of them but they’re rather difficult to extract, having once been formed close to the core of the new planet. They also have a tendency to attach themselves by covalent bonds to other minerals, making them difficult to separate and employ separately. In case you were wondering, in a covalent bond the atoms of the elements involved share one or more of their electrons. But having formed close to the core, some of them move up towards the surface, where they are known as “xenoliths”, from the Greek for foreign rock.

They are, as Natalie Starkey notes in her fascinating book, “Fire and Ice”, which is all about the many and varied volcanoes of the solar system, “an extraneous component within the magma”. They shouldn’t really be there, in other words. They formed under different pressure, temperatures and depths from the conditions they travel through to reach the surface, she explains. Nevertheless, they formed many millions of years ago in the Earth’s mantle, which makes them very instructive to those scientists still trying to work out the Earth’s deepest history. How did it all begin? They’re also rather useful in other fields of endeavour, such as high-tech electronics, computing, and communications, for various reasons.

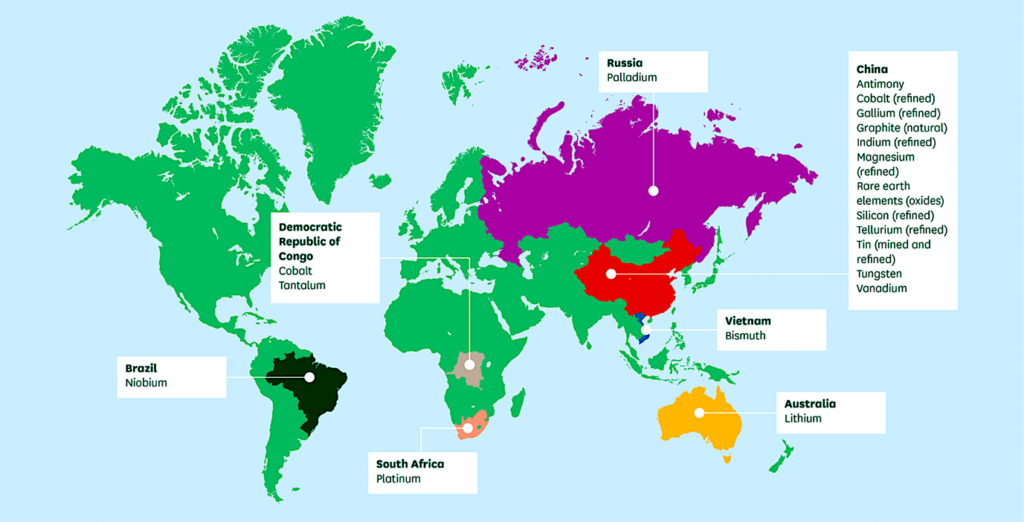

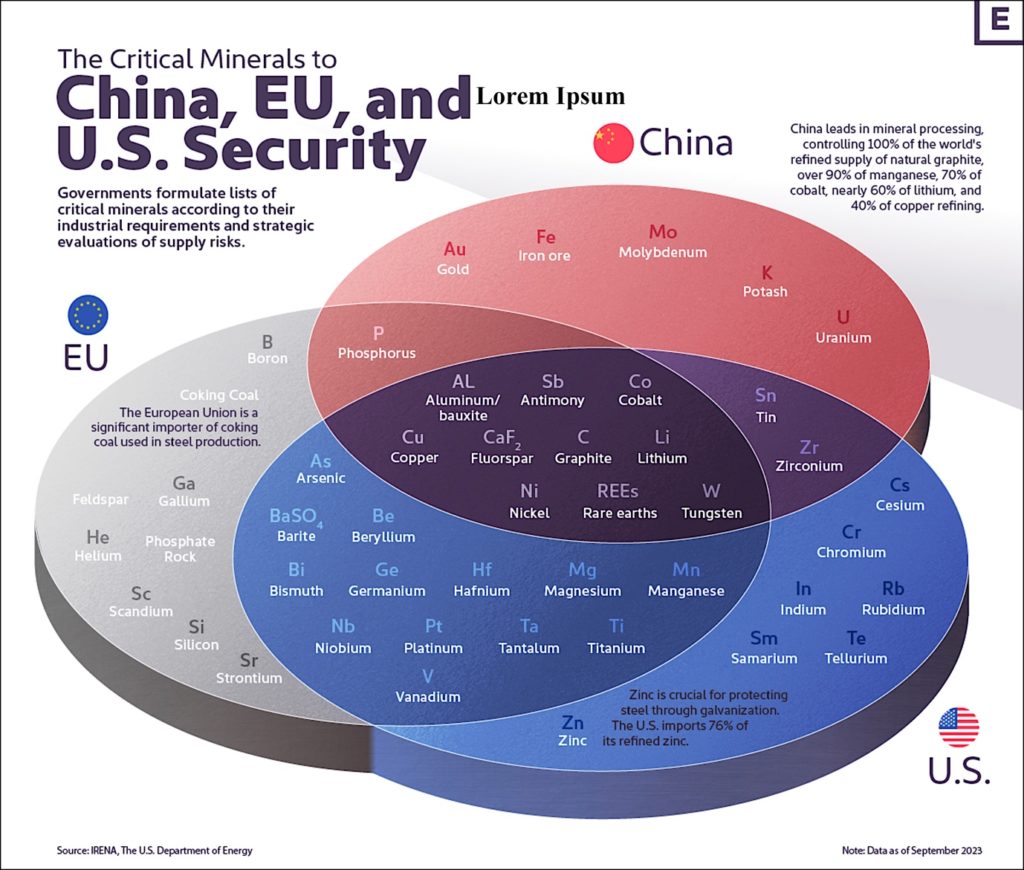

In terms of the worldwide distribution of REEs, China seems to have been blessed with a more than adequate sufficiency, although it is a wealth China appears reluctant to share. Given their importance in our increasingly high-tech world, perhaps that’s not surprising. In fact, they are often described as “technology metals”. In view of their link with ancient, long-dead volcanoes, REEs are useful in dating the eruptions of long ago and learning more about them. But that’s not why China has banned the export of the processing technology for rare-earths: it’s all about national security. In fact, the ban has been placed on the export of the technology to make rare earth magnets, and this is in addition to the existing ban on the technology required to extract and separate critical materials. China, we should remember, is the world’s biggest processor of rare earths, that group of seventeen metals used in the manufacture of magnets that are vital in making electric vehicles, wind turbines and other kinds of electronics because they can be used to turn power into motion. A few months earlier, the Chinese government asked for public opinion on adding the technology to make samarium-cobalt magnets, neodymium-iron-boron magnets and cerium magnets to its long (and ever-lengthening) “Catalogue of Technologies Prohibited and Restricted from Export”. It also added a ban on exporting the technology needed to make rare-earth calcium oxyborate and a number of other rare-earth metals. China gave as its reason for doing so the “protection of national security and public interest”. The protection of its considerable commercial interests may also be a significant issue. They’re worth a lot of money.

| CATCHING UP WITH THE STONE AGE

Why does this matter? Well, as our TV adverts have amply demonstrated recently, electric vehicles are the way to the future, it seems. They’re being promoted as less environmentally damaging, a cleaner technology. But in fact, some of the materials being used to reach this goal are carbon-intensive and environmentally quite harmful. Permanent magnets are no different. Driven by the successful miniaturisation of magnetic materials, the technique is attractive but is not without cost, which makes the choice of the magnetic alloy being used very important. Before the 1980s, the best magnets available in terms of energy-density were made of samarium-cobalt (SmCO), but a Japanese company seeking a less costly solution came up with a nyodymium-iron-boron (NdFeB) magnet, which was found to be cheaper to make and just as powerful. This switch was aided by civil war in the Democratic Republic of Congo (formerly Zaire) from which came much of the global supply of refined cobalt. The conflict made prices unpredictable (mainly it put them up by a considerable amount), so the NdFeB alternative proved to be easier to source, with more stable prices. Ever since then, NdFeB permanent magnets (PMs) have been cropping up everywhere, such as in hard disk drives and electric vehicle power trains. So, NdFeB PMs seem to have become universal, although the older SmCO type have the advantage of being less susceptible to corrosion.

The NdFeB magnet, however, is the most powerful yet developed, at least at the time of writing, which is why it accounts for around 95% of the permanent magnets currently in use.

China’s tighter rules, however, have placed western industry and researchers at a disadvantage. Companies in Western Europe and the United States have sought ways to reduce their dependency on rare earths from China. The fact remains that almost 90% of the refined global output comes from China, which has also mastered the techniques needed to refine the strategic materials. Those places outside of China that have a (somewhat more limited) supply of such things have found themselves much in demand. Nobody seems certain (at least, outside of Beijing) just how much of China’s enviable output and know-how is actually being exported. It is certain, however, that China aims to exploit its many advantages in this field, and who can blame it? The problem was discussed at a 2023 meeting of the International Energy Agency (IEA), but there is clearly deep concern over China’s apparent stranglehold on the processing of materials that can be used in everything from electric vehicles to wind turbines, and – perhaps most alarmingly – missile guidance systems. And China, of course, accounts for more than half of global production of the metals used in batteries, such as lithium, cobalt, and manganese, as well as something approaching 100% of rare earths. That is a very substantial amount. As it is, a trade war has developed between the United States and China over the production of gallium, which is used in semiconductors as well as in military radar systems, among other important things.

China has imposed restrictions on exporting it, of course. Gallium is a substance sometimes used by young (and quite often inebriated) chemists to play tricks on each other. What happens is that the chemists (mainly students, it must be admitted) make a spoon out of gallium (it is a metal, after all and looks convincing) and when the victim has stirred their tea or coffee and removed the spoon from the cup, they find it has disappeared, and so they drink gallium in the beverage (or probably throw it away, I imagine; I know I would). It’s said to be harmless to human health, although it can stain the skin dark brown. Perhaps it’s a trick that’s popular among French students, as gallium is named after the Latin word for France (Gallia).

The neodymium-iron-boron magnet was found to be stronger than any other known magnet and it revolutionised the low-cost mass production of what are called permanent magnets, making possible the production of smaller motors and hard disk drives. Without this technology, we would be living in a somewhat more primitive and far less technically advanced society. Think about it the next time you use your mobile phone or your laptop. China, of course, has mastered the solvent extraction process needed to refine strategic minerals, a skill that Western companies are struggling to match. The research currently being carried out in the United States to find a solution is being funded, at least partially, by the US Department of Defense, which suggests where the greatest interest lies.

| KEEP SEARCHING

There are seventeen rare-earth elements in all, fifteen of which make up what’s called the lanthanide series, with atomic numbers ranging from 57 to 71 consecutively. We’ve already met neodymium, which is used in permanent magnets, but there are others that are also useful. There’s dysprosium, for instance, which is one of the most highly magnetic elements in existence in its natural form, and is used in electronics, computer disks, various kinds of recording equipment and in the production of powerful infrared lasers. If you’re engaged in making telescope lenses or infrared absorbent glass, on the other hand, you’ll need lanthanum. Or there’s yttrium, the silvery-coloured metal that’s used in superconductors, lasers, and in surgical supplies. So just how rare are these rare-earth elements? Not so rare as you might imagine. Even the rarest of them, thulium, is still 125 times as abundant as gold, while the commonest of them, cerium, is 15,000 times as common. Separating them from other elements is where it gets difficult and very expensive. Furthermore, so far no-one has discovered suitable alternatives with which to replace them, although the EU’s Horizon 2020 programme is trying to do just that, aided by funding of around €15.09-million, while a research team at Birmingham University in the UK is working towards a similar goal, supported by €5.06-million provided by SUSMAGPRO, which stands for Sustainable Recovery, Reprocessing and Reuse of Rare Earth Magnets in a European Circular Economy. Finding ways to recover and re-use such elements, in other words. The researchers there say they’re confident that the new technology they’re developing will be able to produce some twenty tonnes each year of recycled rare earth magnets.

It’s an encouraging thought: germanium and gallium are both key to the production of semiconductors. It was germanium that was used to make the very first transistors, so we children of the 1960s should be very grateful because they enabled us to annoy older people with our music, and it’s still vital for thermal imaging cameras, solar panels and the fibre optics used in telecommunications. China has a tight grip on the production of gallium, as well as controlling 68% of the global production of refined germanium., according to the US Geological Survey. Gallium, meanwhile, is vital for the production of the gallium arsenide chemical compound (GaAS) which allows semiconductor junctions to operate at higher frequencies and temperatures than those made with silicon. China has a virtual monopoly on gallium and germanium thanks to some clever manoeuvring on world mineral markets during a period of surpluses in the years from 2012 to 2017. China has clearly mastered the mysteries of capitalism, too. Meanwhile, Western companies are playing down the likely impact of China’s sanctions and export restrictions, although it’s hard to see why. 70% of the gallium Japan imports each year comes from China and car manufacturers are concerned about the prospect of a shortage of chips, but most Western governments seem to be doing little to encourage the search for alternative sources or alternative methods and materials The policy of the West as a whole would appear to be one of complacency, despite the concern expressed by some car manufacturers. Volkswagen has expressed an interest in taking whatever measures are necessary to retain its supplies while the chairman of France’s Renault company has warned of a “Chinese storm” on the horizon. Western companies are being urged to cooperate in confronting the Chinese threat, even if that means setting aside their tendency towards nationalism when faced with any crisis.

I feel I must just mention here, however irrelevant, that the report I was studying about the growing crisis kept leaving the middle “m” out of germanium and added a superfluous “s” to the end of the word. It was probably the result of some sort of computer spell-checking programme. I’m sorry to say that the thought of western nations holding crisis talks because of the risk that China had cornered the global market in geraniums made me laugh out loud. It’s a lovely vision and much more amusing than what’s really been happening. Want a geranium, anyone? But I digress.

The Council of the European Union expects the demand for rare earth elements to increase exponentially in the years immediately ahead. It believes that by 2040 there will be four times the current demand for critical minerals and clean energy technologies. The UK government, for one, accepts that mineral supply chains are “complex and opaque”, the market itself is “volatile and distorted” and that China is very much the dominant player. It also accepts that “jobs and industries rely on minerals that are vulnerable to market shocks, geopolitical events and logistical disruptions at a time when global demand for these minerals is rising faster than ever.” Needless to say, the UK (like other countries) has a strategy to address the growing crisis. This will involve accelerating the growth of the UK’s domestic cap on overuse within its borders, collaborating with international partners and enhancing international markets to make them “more responsive, transparent and responsible”. It doesn’t mention how it plans to achieve this miracle, which will be harder since Britain left the EU. Working together with others in cooperation is invariably a more sensible way to approach such problems.

| WAYS THROUGH THE MAZE

The EU, of course, has its own plans for minimising damage resulting from China’s near-monopoly on rare-earth elements. In November 2023, the Council reached a provisional agreement on what it called a “European critical raw materials act”, which looks like a good idea, especially with the fast-growing demand for rare-earth elements that looks set to continue. The Act specified raw materials that are of high economic importance for the EU but which face a high risk of supply disruption while affordable substitutes either do not exist or are not available. In order to address this crisis, the EU plans to diversify supply of the EU’s critical raw materials (if it can), strengthen what it calls “circularity” (which basically means improving recycling), and support for research and innovation on what it refers to as “resource efficiency” (which probably means “waste not, want not”), along with the development of substitutes, if any can be found. Basically, the problem here is that many of Europe’s defensive systems rely on the availability of rare-earth elements, of which we have relatively few, and China has lots. It’s not a pretty picture.

The West’s somewhat panicky response to the crisis so far is, of course, an invitation to Western firms to come up with a profitable solution. For instance, the US-based Noveon Magnetics company extracts materials from discarded commercial magnets. As the old saying goes: “waste not, want not”.

However, with China closing the door to exports, it’s getting increasingly difficult to ensure that the supply of such elements stays stable. The International Energy Agency (IEA) is convinced that demand for REEs will reach up to seven times its current level by 2040, while demand for lithium and certain other vital and hard-to-obtain substances may soar to 40-times its present level. There are several ways to obtain the necessary REEs: mining, if you have access to such supplies, recovery from end-of-life products – recycling, in other words – or extracting them from unconventional sources, which includes such industrial wastes as coal ash and waste material from mining. The US has one active mine producing REEs: the Mountain Pass Rare Earth Mine and Processing Facility in California, but opening a new mine – even supposing you can find the material you’re after – can take decades. That’s why so many scientists are devoted to looking into unconventional alternative sources, and not without good reason: all but one of the 17 Rare earth elements are listed as “critical materials”, which means they’re economically very important but vulnerable to supply issues.

The Massachusetts Institute of Technology (MIT) points out that the list includes praseodymium, which is used in aircraft engines, gadolinium, which plays a vital part in MRI imagining and neodymium, which can be found in computer hard drives. The “rare” description in REEs refers to how difficult it is to find them in commercially exploitable volumes: there’s no real shortage but what there is can barely justify the effort involved in getting them out of the ground. They’re scattered in tiny quantities in a great many locations. Even so, coal ash – the leftover waste from coal-fired power plants – contains small concentrations of REEs and could emerge as a vital domestic source and is generally mixed with water to form a kind of slurry and stored in ponds. These ponds are quite dangerous to the environment and can, if not carefully contained, contaminate local water supplies with mercury, cadmium, and arsenic. In fact, research in the US has shown that the majority of these ponds (and there are lots of them) have been and still are polluting nearby groundwater. Extracting the required Rare earth elements is no easy task, in addition to which extreme weather events can spread the poisons far and wide. Obtaining the desired materials is a struggle and successful methods are swiftly patented: they’re very valuable. Rivalia Chemical is one of the companies at the forefront of this research, backed by Georgia Institute of Technology.

So, it’s a long and winding road with no easy short cuts, but it’s vitally important to reach the end of it in order to secure technological progress. It’s possible, of course, that we could find supplies of REEs on those other planets that have experienced vulcanism, but we cannot – as yet – get to the places and prospect for them. In the long term, they may provide a solution, but we’re not there yet. Even where they’re known to exist, it is often in very minute quantities. Half of the 5,000 or so minerals to be found on Earth exist in five or fewer locations, while the volume of some appears to be less than one cubic centimetre. What’s more, some of the minerals to be found on Earth are rarer than REEs and evaporate on contact with air or decompose on exposure to sunlight. Hazenite, for instance, is a hydrous phosphate that is only found in the highly-alkaline waters of California’s Mono Lake, where it is precipitated out by microbes. Minerology is an interesting but frustrating study. A crystalline form of carbon dioxide is only stable at below -78.5 °C, although it has been spotted on Mars. The more we progress, the more the challenges mount. If we ever learn how to work together without killing each other, we may even go further towards a bright future. Anyone want a geranium?